Due to extremely high demands on quality and reliability in the automotive industry and its low dppm (defective parts per million) standards, every failure of a unit (control device, module, component) has to be analyzed according to its failure cause. This is necessary for every unit in the qualification, the production at the suppliers, the production at the assembly line of the OEMs (0km-failures) and when operated by the car owner (field failures).

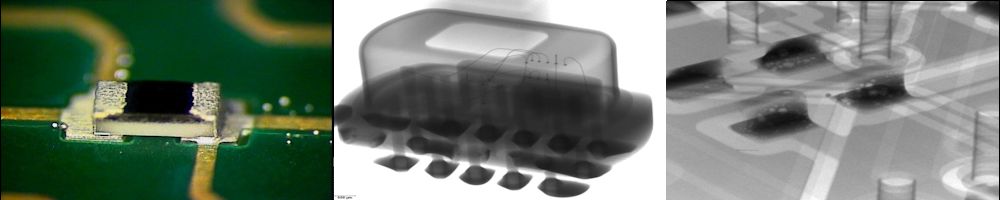

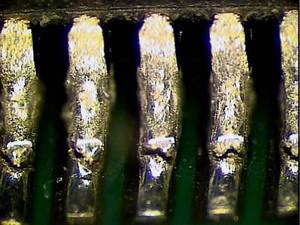

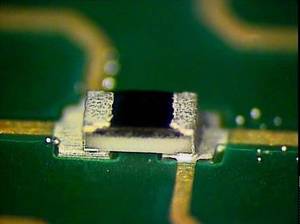

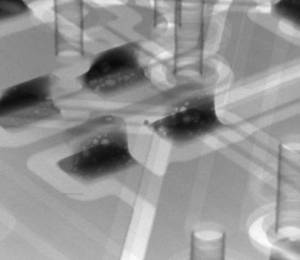

The failure analysis of devices, modules and components requires an up-to-date device equipment according to analysis technics and long-term experienced employees in engineering and physics. Without the necessary knowledge in analysis methods and experience with error patterns and the related error mechanism, there is no well-founded retraceable analyse available.

Because of that TSQE cooperates with the error analysis laboratory of RoodMicrotec in Stuttgart-Weilimdorf. It enables TSQE to coordinate the error analysis from customer complaint to surveillance of correct actions and their efficiency by order.